Introducing the Small Water-Cooled Fiber Laser Welder

troducing the future of metalworking: our groundbreaking fiber laser welding, cutting and cleaning machine and clean weld gaps. Designed to transform the welding industry, this state-of-the-art technology offers 3 laser power options, 1.5KW, 2kW and 3kW laser sources, providing unmatched versatility and performance for all your metal fabrication needs. Imagine a world where precision and efficiency come together seamlessly. With the DH fiber laser welder, you can achieve perfect welds, precise cuts and perfect cleaning at unprecedented speeds. Learn more about the laser welder here. Its advanced laser beam technology harnesses the power of focused light to deliver unparalleled precision and welding speeds. Say goodbye to traditional welding methods that require extensive manual labor and embrace the future of metalworking.

Advantages of Fiber Laser Welding

Advantages of Fiber Laser Welding Ease of Use Fiber laser welders are easy to use, even for people with no welding experience. This ease of use helps shorten learning time and lead to wider adoption in a variety of environments. High Efficiency Fiber laser welders have a far lower energy efficiency ratio than other welding methods, significantly reducing operating costs compared to traditional welding techniques. Precision and Quality Fiber laser welders offer superior precision, providing consistent, clean, and high-quality welds. Precision helps minimize thermal distortion, which is critical for complex and sensitive welding tasks. Speed Fiber laser welders are able to perform welding tasks at higher speeds, increasing productivity and reducing manual production cycles without compromising weld quality. Versatility Fiber laser welders can handle a wide range of materials, including stainless steel and mild steel, as well as challenging metals such as aluminum and copper. This versatility makes them suitable for a wide range of industrial welding applications. Minimal Maintenance Fiber laser welders use a solid-state design and fewer moving parts, minimizing maintenance requirements. This reliability means less downtime and lower ongoing maintenance costs.

Why Upgrade To Fibre Laser Welding

Not only does our laser welding machine revolutionise productivity, but it also ensures uncompromising quality. The precision beam allows for welds that are stronger and more durable, eliminating the risk of weak joints. And when it comes to cleaning, the laser effortlessly removes surface contaminants, leaving a pristine finish behind. Beyond its exceptional performance, our laser machine boasts a user-friendly interface, alongside a range of safety features, making it accessible to both seasoned professionals and newcomers in the industry. Its intuitive controls and automated features streamline the workflow, reducing training time and increasing overall efficiency. Experience the revolution firsthand and take your craftsmanship to new heights. Don’t miss the opportunity to be at the forefront of innovation.

What services can we provide to our customers?

A good device is just the beginning. The real value lies in providing customers with comprehensive solutions and considerate services, and is committed to becoming a long-term partner that customers can trust. Tailor-made: Each customer’s needs are unique. We will communicate in depth to understand your product characteristics, production scale, budget range, etc., and combine our rich industry experience to recommend the most suitable laser welding machine model and configuration for you. Professional training: Equipment delivery is just the beginning of service. We provide comprehensive operation training to ensure that your team can use the equipment proficiently and give full play to its performance advantages. At the same time, we will also share industry experience and process skills to help you quickly improve welding efficiency and product quality. Quick response: We have established a complete after-sales service system and provide 7*24 hours of quick response service. No matter what problems you encounter, our professional engineer team will provide you with remote or on-site support as soon as possible to ensure that your production goes smoothly. Integrity management: Integrity is the foundation of our business. We always adhere to transparent quotations, never exaggerate product performance, and never conceal any potential problems. We believe in treating each other sincerely.

.jpeg) PROFESSIONAL

FIBER LASER PIPE CUTTING MACHINE

PROFESSIONAL

FIBER LASER PIPE CUTTING MACHINE

.jpeg) CANTILEVER

CUTTING MACHINE

CANTILEVER

CUTTING MACHINE

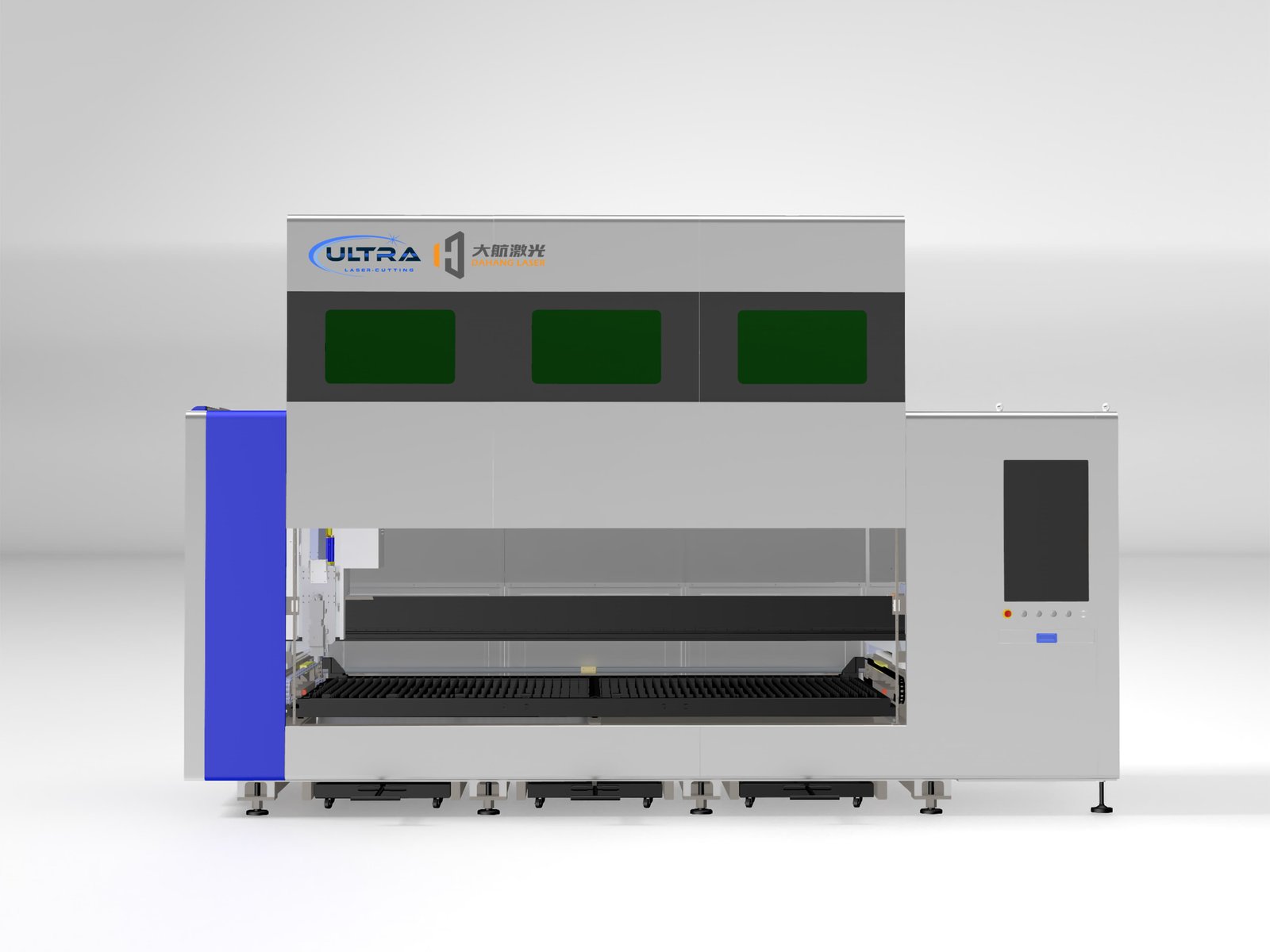

SINGLE PLATFORM SIDE EXIT ENCLOSED

HIGH SPEED FIBER CUTTING MACHINE

SINGLE PLATFORM SIDE EXIT ENCLOSED

HIGH SPEED FIBER CUTTING MACHINE